Marine Coatings

Producing all currently specified coatings including Ceramic Chrome plating, Plasma and High Velocity Oxygen Fuel (HVOF) sprayed coatings, PPUK supports the comprehensive and demanding range of engine sizes including all current 2 stroke and 4 stroke diesel engines. If you need any assistance in finding the right product for your application, please contact us

C1 - Nickel Graphite

C2 - Plasma Sprayed

Photo-Micrographs

Coating Description

A thin layer of copper is applied on the running surface of piston rings to help them bed-in during their first few hours in operation. Copper running–layers can be applied directly onto base material or on other coatings. This coating is very thin and only survives until full load is applied to the engine.

General Information

Application Universal

Performance Bed-in Coating

Thickness 0.050 – 0.075 mm

C4 - Hard Chrome

C5 - RIAS

Photo-Micrographs

Coating Description

The C5 coating consists of two sprayed layers the first is Molybdenum and the second is Nickel Graphite. This coating is commercially referred to as RIAS.

General Information

Application 4 stroke engines

Performance Running-in/wear resistance

Thickness Mol (0.050 – 0.075mm) NG (0.050 – 0.075mm)

C6 - Aluminium Bronze

C7 - Molybdenum

C10 - Ceramic Chrome

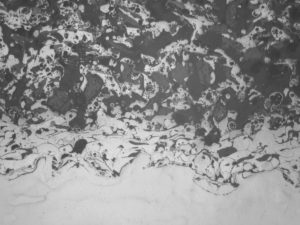

Photo-Micrographs

Coating Description

Ceramic Chrome is a special type of coating consisting of a mix of hard chrome filled with non-metallic ceramic particles to reduce friction between rings and liners, minimize wear and extend ring’s life

Ceramic Chrome enjoys superior characteristics over conventional hard chrome such as low coefficient of friction, good thermal stability, good wear resistance and better scuffing resistance.

General Information

Application 2 & 4 stroke engines

Performance Wear Resistance

Thickness 0.18 – 0.60 mm

Hardness 850 – 1010Hv0.1

C11 - HVOF Sprayed Coatings

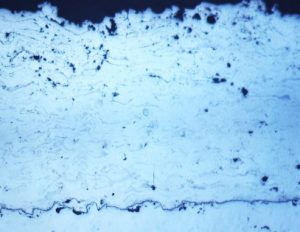

Photo-Micrographs

Coating Description

HVOF sprayed coatings are used for their enhanced tribological and mechanical properties, they offer good corrosion and wear resistance for piston rings. A variety of coating combination can be produced using this process.

General Information

Application Top piston rings

Performance Wear Resistance

Thickness Up to 0.60mm