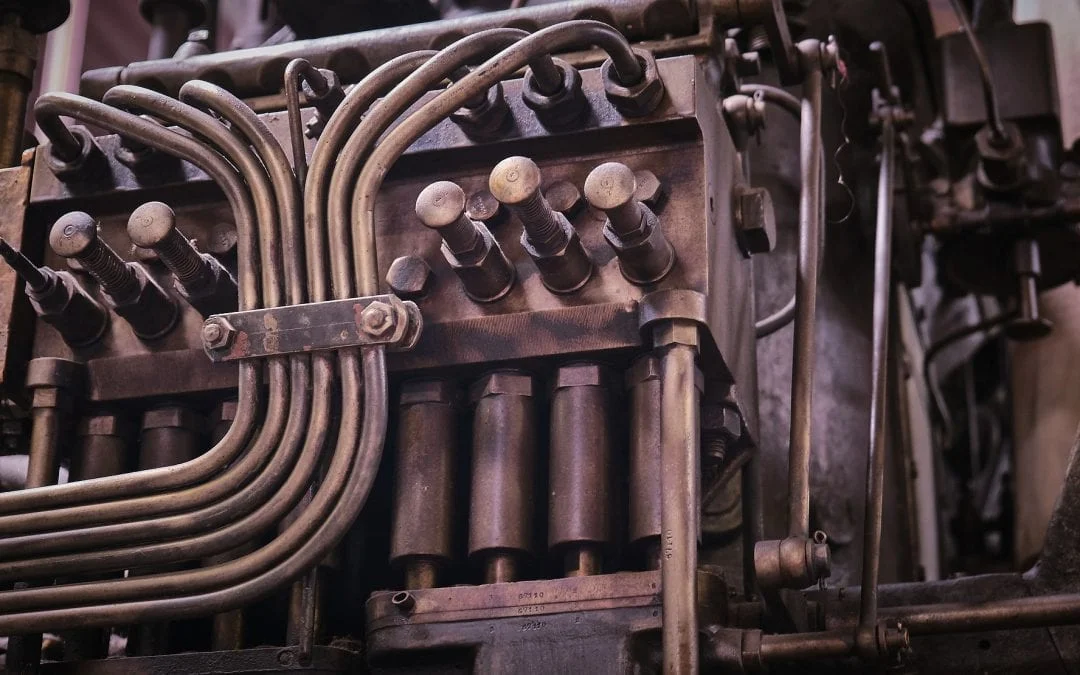

Piston rings operate at higher temperatures than fabric, elastomeric, or polymer seals. If damaged, sealing rings allow engine oil to become polluted by hot exhaust leaking from the cylinder into the crankcase.

So what are piston rings made of and how do these products lead to a better long-term performance in industrial and marine engines?

What are industrial & marine piston rings made of?

Piston rings are designed with large engines in mind. Typically made in a foundry from cast iron, graphite iron, or a related alloy, they can withstand high temperatures – but without compromising on performance.

Whichever material is used to construct marine or industrial piston rings, it must satisfy the following requirements:

- Minimal Friction. Piston rings must be able to move continuously across the surface of a cylinder – the temperature of which will vary – and with minimal lubrication.

- High Elasticity. The ability to exert pressure on a cylinder without breaking or seizing upon contact is essential. Rigid materials will lack the inherent plasticity needed to succeed under such conditions.

- All-Round Strength. Cast iron is strong and hard, making it the ideal choice for components designed to work around the clock and under unforgiving conditions.

That’s why it’s important to work with a piston ring manufacturer you can trust. Not all products are created equally – and so it’s important to choose a partner with relevant expertise and a demonstrable track record of success.

Worldwide Piston Ring Manufacturers You Can Trust

Our sealing rings are made using state-of-the-art equipment operated by industry experts. We’re part of the Made in Britain campaign too, an initiative designed to support the UK manufacturing sector.

Contact us now to discuss your requirements in more detail.